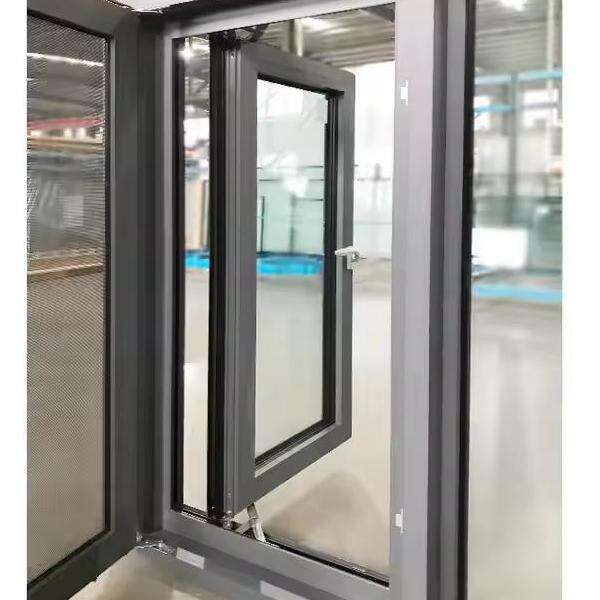

new heat insulation thermal break aluminum doors and windows

New heat insulation thermal break aluminum doors and windows represent a revolutionary advancement in modern building solutions, combining superior thermal performance with exceptional durability and aesthetic appeal. These innovative window systems feature a sophisticated design that incorporates thermally broken aluminum frames with specialized insulation materials, creating an effective barrier against heat transfer between interior and exterior environments. The thermal break technology utilizes polyamide strips or similar insulating materials inserted between the inner and outer aluminum profiles, preventing thermal bridging and significantly reducing heat loss during winter months while maintaining cool indoor temperatures during summer. The main functions of new heat insulation thermal break aluminum doors and windows include temperature regulation, energy conservation, noise reduction, and weather protection. These systems effectively minimize condensation formation on window surfaces by maintaining consistent interior surface temperatures, preventing moisture-related issues that can lead to mold growth and structural damage. Technologically, these windows incorporate multi-chamber aluminum profiles with precision-engineered thermal barriers that achieve impressive U-values, often ranging from 1.2 to 2.0 W/m²K depending on glazing configurations. The aluminum frames undergo specialized surface treatments including powder coating, anodizing, or wood grain finishing to enhance corrosion resistance and provide diverse aesthetic options. Advanced glazing options include double or triple-pane configurations with low-emissivity coatings, argon gas fills, and warm-edge spacers that further enhance thermal performance. Applications for new heat insulation thermal break aluminum doors and windows span residential homes, commercial buildings, office complexes, hospitals, schools, and industrial facilities where energy efficiency and climate control are priorities. These systems prove particularly valuable in extreme climate regions where temperature differentials between indoor and outdoor environments are substantial, helping building owners achieve significant energy savings while maintaining optimal comfort levels for occupants throughout all seasons.