the thermal break aluminum doors and windows customization

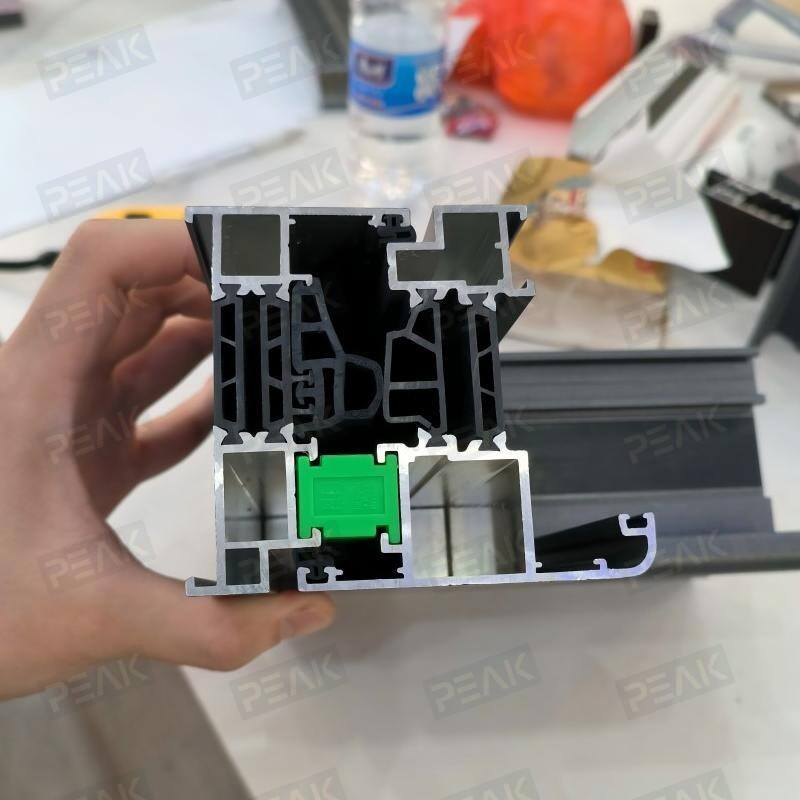

Thermal break aluminum doors and windows customization represents a cutting-edge solution in modern architectural design, combining aesthetic appeal with superior thermal performance. This innovative system utilizes advanced polyamide strips between the interior and exterior aluminum profiles, creating an effective barrier against thermal transfer. The customization process allows for precise specifications in dimensions, styles, and finishes, ensuring perfect integration with any architectural design. The system's core technology involves a mechanical rolling process that securely connects the thermal barrier to the aluminum profiles, creating a robust and durable structure. These custom solutions offer exceptional insulation properties, reducing heat loss in winter and heat gain in summer, while maintaining the structural integrity and sleek appearance of aluminum. The system can be tailored to various applications, from residential homes to commercial buildings, with options for different glass packages, hardware configurations, and surface treatments. Advanced manufacturing processes ensure tight tolerances and precise fits, resulting in superior weatherproofing and acoustic performance.