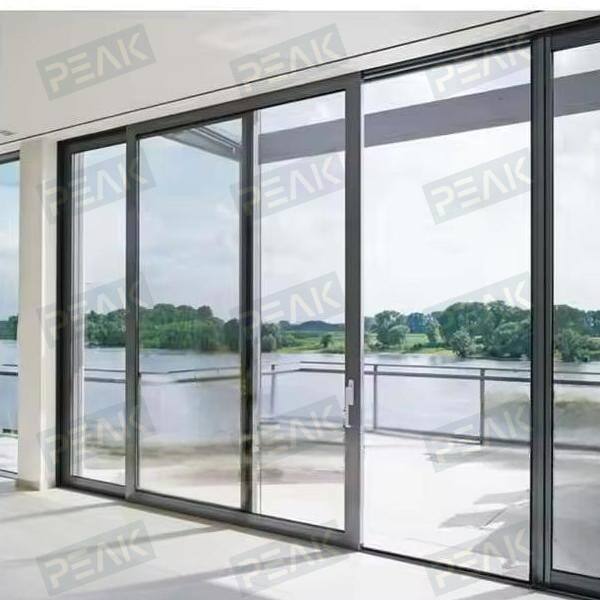

Unmatched Customization Flexibility for Perfect Architectural Integration

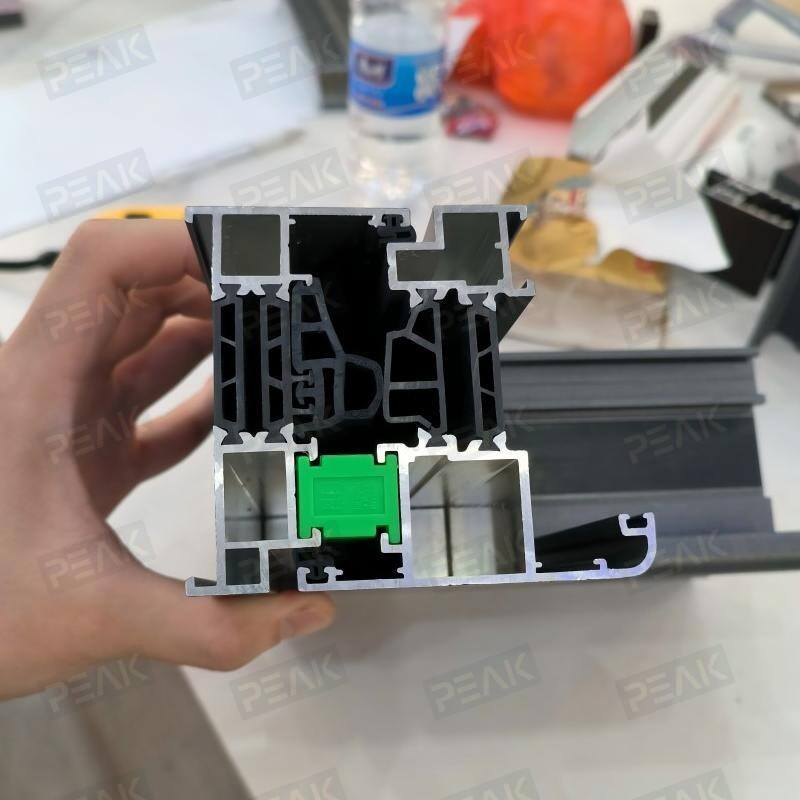

Popular thermal break aluminum doors and windows customization offers unprecedented flexibility in design adaptation, enabling seamless integration with virtually any architectural style or functional requirement. The customization process begins with comprehensive site evaluation and design consultation, where specialists assess existing conditions, architectural constraints, and performance objectives to develop tailored solutions. Frame configurations can be modified to accommodate unique opening sizes, irregular shapes, and specialized installation conditions that standard products cannot address. Color customization extends far beyond basic selections, with advanced powder coating techniques enabling precise color matching to existing building elements or architectural specifications. Special finishes including wood grain textures, metallic effects, and matte surfaces provide additional aesthetic options for distinctive design applications. Hardware customization encompasses operating mechanisms, locking systems, and decorative elements, allowing complete coordination with interior and exterior design themes. The ability to specify glazing combinations enables optimization for specific performance criteria, whether prioritizing maximum energy efficiency, enhanced security, noise reduction, or specialized applications like hurricane resistance. Frame depth customization accommodates various wall thicknesses and construction methods, ensuring proper integration with both new construction and retrofit applications. Specialized features can be incorporated during manufacturing, including integrated blinds, ventilation systems, smart home compatibility, and accessibility enhancements. The customization process extends to installation details, with specialized mounting systems and weatherproofing solutions adapted to unique building conditions. Quality control procedures ensure that customized elements meet the same rigorous performance standards as standard configurations, maintaining structural integrity and energy efficiency regardless of modifications. Professional project management coordinates all customization elements, ensuring seamless integration from design through installation completion, while maintaining realistic timelines and cost parameters.