high quality thermal break aluminum doors and windows customization

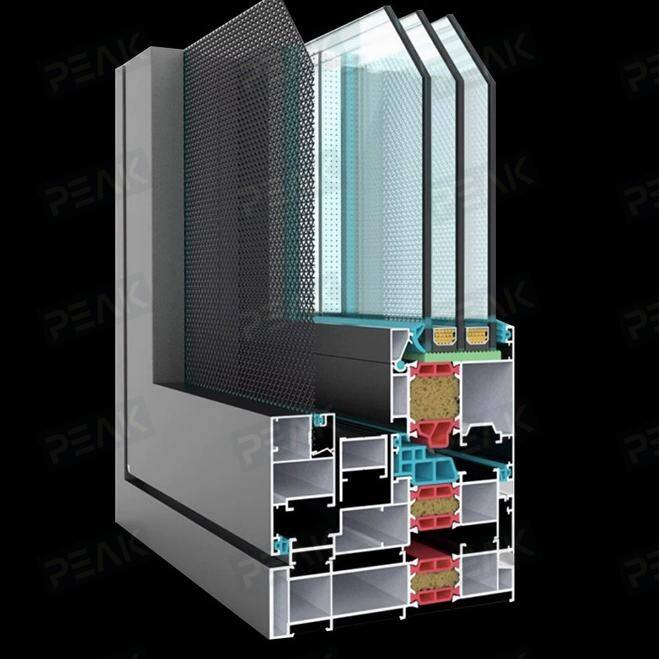

High quality thermal break aluminum doors and windows customization represents a revolutionary approach to modern building design, combining advanced engineering with personalized architectural solutions. These specialized systems utilize cutting-edge thermal barrier technology that effectively interrupts heat transfer between interior and exterior environments, delivering exceptional energy performance while maintaining structural integrity. The customization aspect allows architects, builders, and homeowners to create tailored solutions that perfectly match specific design requirements, dimensional constraints, and performance specifications. The core technology involves inserting polyamide strips or thermal barriers between aluminum profiles, creating a physical separation that prevents thermal bridging. This innovative construction method significantly reduces heat conductivity while preserving the inherent strength and durability characteristics of aluminum framing systems. Customization capabilities extend across multiple dimensions including frame profiles, glazing configurations, hardware selections, color finishes, and operational mechanisms. Advanced manufacturing processes enable precise fabrication of complex geometric shapes, oversized panels, and specialized configurations that traditional standardized products cannot accommodate. These systems incorporate multi-chamber designs that enhance insulation properties while accommodating various glazing options including double, triple, and specialized performance glass units. Weather sealing systems utilize multiple compression seals and drainage channels to ensure optimal protection against water infiltration and air leakage. The aluminum substrate provides excellent resistance to corrosion, UV degradation, and structural deformation while supporting extensive customization through powder coating, anodizing, and specialized surface treatments. Integration capabilities include compatibility with automated opening systems, security hardware, and smart building technologies. Applications span residential, commercial, and institutional projects where superior thermal performance, aesthetic flexibility, and long-term durability are essential requirements for successful architectural outcomes.