thermal break aluminum doors and windows customization

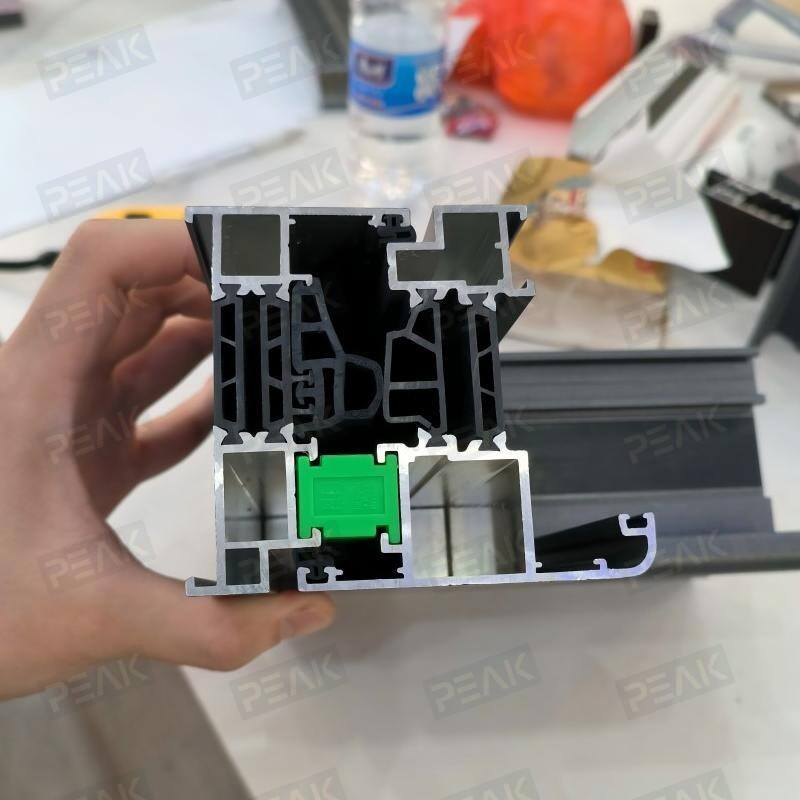

Thermal break aluminum doors and windows customization represents a revolutionary advancement in building envelope technology, combining the strength and durability of aluminum with superior thermal performance. This innovative solution addresses the primary weakness of traditional aluminum frames through the integration of thermal break technology, which prevents heat transfer between the interior and exterior aluminum components. The customization aspect allows architects, builders, and homeowners to create bespoke solutions that perfectly match their specific requirements, whether for residential, commercial, or industrial applications. The thermal break system works by inserting non-conductive materials, typically polyamide strips, between the inner and outer aluminum profiles, effectively breaking the thermal bridge that would otherwise allow heat to transfer through the frame. This technology significantly improves the overall energy efficiency of buildings while maintaining the aesthetic appeal and structural integrity that aluminum is known for. The customization process involves precise engineering and manufacturing techniques that enable the creation of windows and doors in virtually any size, shape, or configuration. Advanced software modeling allows for the optimization of thermal performance, structural load calculations, and wind resistance parameters for each unique project. The manufacturing process incorporates state-of-the-art machinery and quality control systems to ensure that every custom thermal break aluminum door and window meets the highest standards of performance and reliability. These systems can accommodate various glazing options, including double and triple-pane configurations, low-emissivity coatings, and gas fills for enhanced thermal performance. The applications for thermal break aluminum doors and windows customization are extensive, ranging from luxury residential projects and commercial office buildings to specialized industrial facilities and historic renovation projects where maintaining architectural authenticity is crucial.