Versatile Design Options and Customization

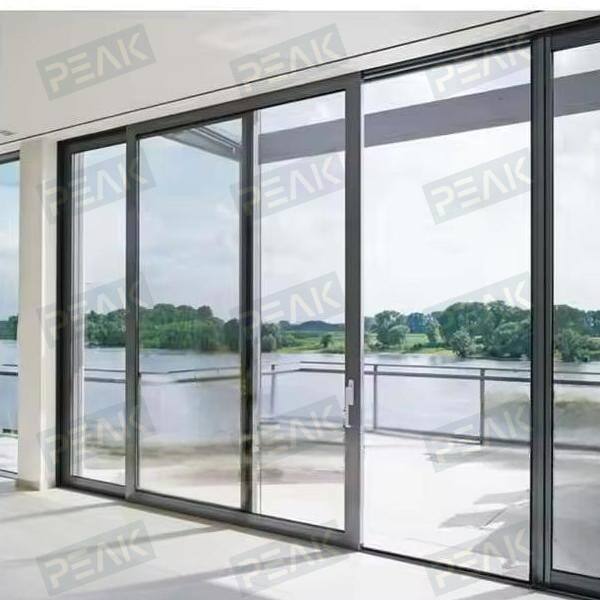

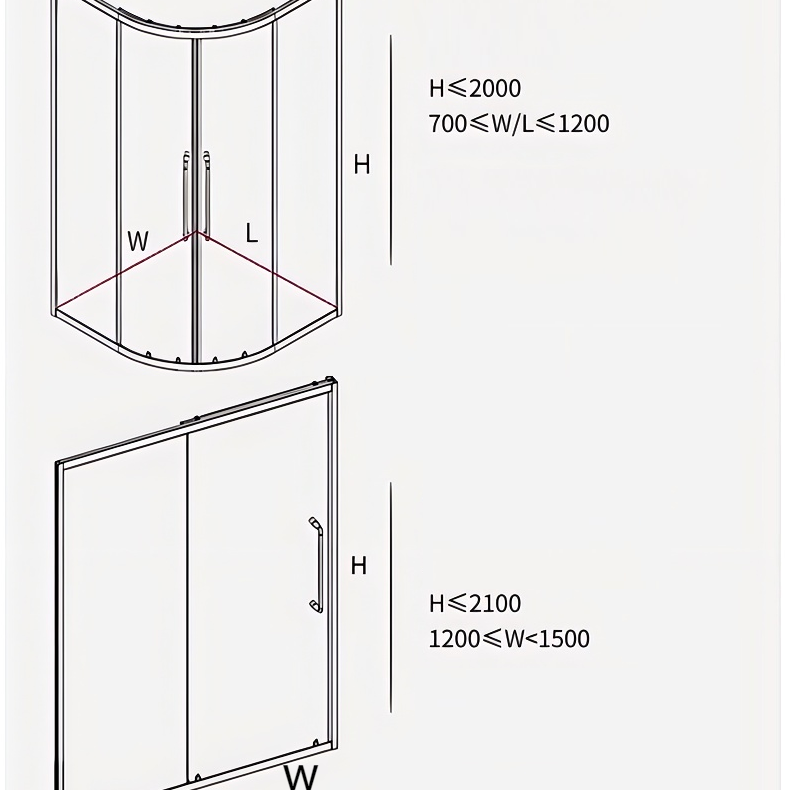

The thermal break aluminum doors and windows price for different types encompasses extensive customization possibilities that accommodate diverse architectural styles, performance requirements, and aesthetic preferences. Modern manufacturing techniques enable precise fabrication of custom sizes, configurations, and specialized features that traditional window systems cannot match. Property owners can select from numerous frame colors including standard architectural finishes, wood grain textures, and metallic effects that complement existing building materials and design themes. The thermal break aluminum doors and windows price for different types includes options for different glazing specifications such as low-E coatings, laminated safety glass, acoustic insulation, and decorative patterns that enhance both performance and visual appeal. Hardware selections range from contemporary minimalist designs to traditional styles, with finishes including brushed nickel, bronze, black, and custom color matching. The structural strength of aluminum profiles allows creation of large glass areas and expansive openings that maximize natural light penetration and outdoor views. Thermal break aluminum doors and windows price for different types accommodates specialized applications including hurricane-resistant systems, blast-resistant configurations, and high-security installations for institutional buildings. The flexibility extends to operating styles including casement, awning, sliding, tilt-turn, and fixed configurations that suit specific ventilation and access requirements. Integrated features such as built-in blinds, automatic operators, and smart home connectivity represent additional customization options that enhance functionality and convenience. The thermal break aluminum doors and windows price for different types supports sustainable design goals through recycled aluminum content and energy-efficient operation that contributes to green building certifications. Architects and designers appreciate the creative freedom these systems provide, enabling innovative fenestration solutions that balance performance, aesthetics, and budget considerations. The manufacturing precision ensures consistent quality across custom orders, maintaining the same performance standards regardless of size or configuration complexity.