excellent thermal break aluminum doors and windows customization

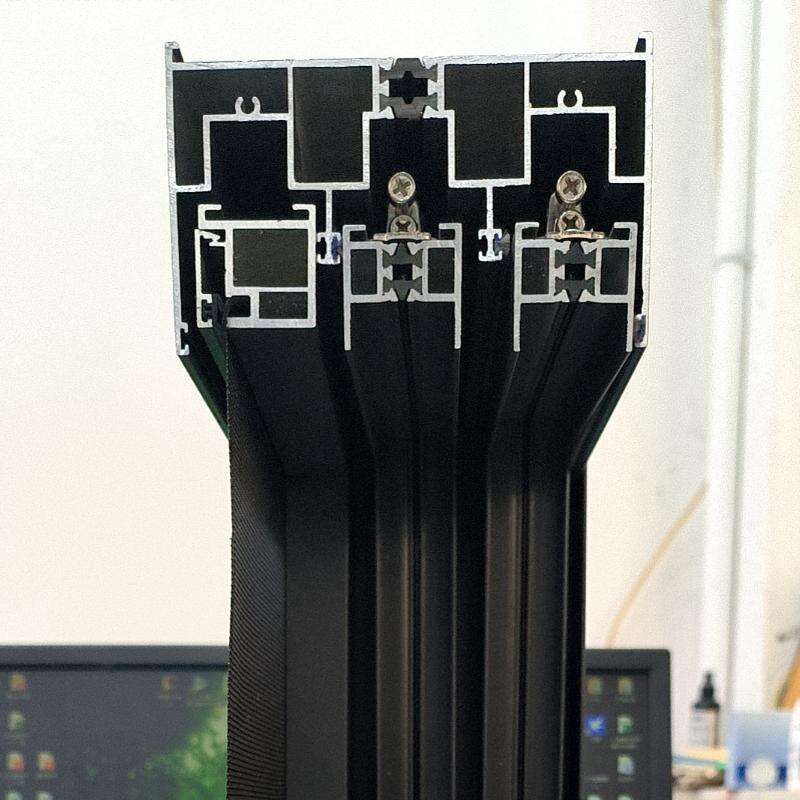

Thermal break aluminum doors and windows customization represents a cutting-edge solution in modern architectural design, combining superior insulation properties with aesthetic excellence. This innovative system utilizes advanced polyamide strips between the interior and exterior aluminum profiles, creating an effective thermal barrier that significantly reduces heat transfer. The customization process allows for precise specifications in dimensions, styles, and finishes, ensuring perfect integration with any architectural project. These systems offer exceptional energy efficiency, with U-values that meet or exceed industry standards, while maintaining the structural integrity and durability characteristic of aluminum construction. The manufacturing process incorporates state-of-the-art CNC technology for precise cuts and joints, ensuring optimal performance and longevity. The systems can be tailored to include various glazing options, from double to triple-pane configurations, with gas-filled cavities for enhanced thermal performance. Additionally, the customization extends to hardware selection, color finishes, and special features such as sound insulation and security enhancements, making these systems versatile solutions for both residential and commercial applications.