Comprehensive Customization Options for Every Application

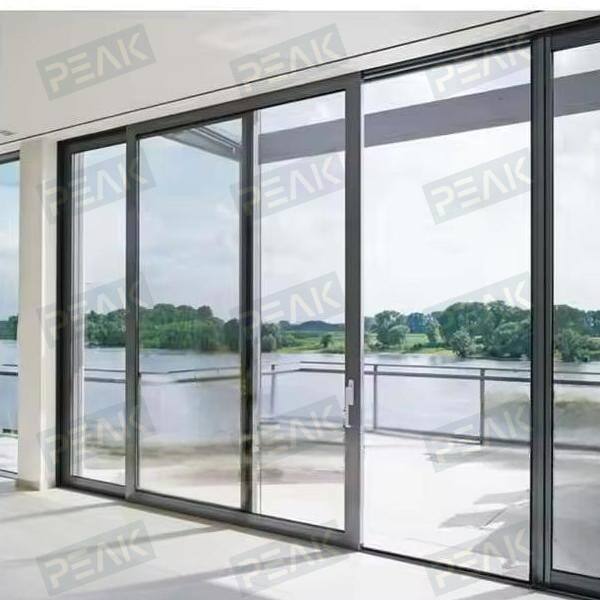

The customization capabilities of the best thermal break aluminum doors and windows customization extend far beyond standard sizing adjustments, encompassing comprehensive design flexibility that addresses unique architectural requirements and performance specifications. Professional design consultation services work directly with architects, contractors, and property owners to develop tailored solutions that optimize both aesthetic integration and functional performance. Color selection includes extensive powder coating options that provide durable, fade-resistant finishes in virtually any desired shade, from classic neutrals to bold contemporary accents that complement specific design themes. Profile configurations accommodate various operational styles, including casement, sliding, tilt-and-turn, and fixed window options, as well as hinged and sliding door systems with different threshold configurations. Hardware selection encompasses security features, accessibility options, and decorative elements that enhance both functionality and visual appeal. The best thermal break aluminum doors and windows customization process includes detailed performance specification development, considering factors such as wind load resistance, water infiltration protection, air leakage control, and structural loading requirements. Glazing options range from standard clear glass to high-performance low-emissivity coatings, impact-resistant materials, and specialized acoustic or security glazing systems. Frame depth variations accommodate different insulation requirements and glazing configurations while maintaining structural integrity and thermal performance standards. Manufacturing flexibility enables production of oversized units, complex geometric shapes, and integrated systems that combine multiple window and door elements within single frame assemblies. Quality control measures throughout the customization process ensure that specialized features maintain compatibility with standard components while meeting or exceeding performance requirements for specific applications and environmental conditions.