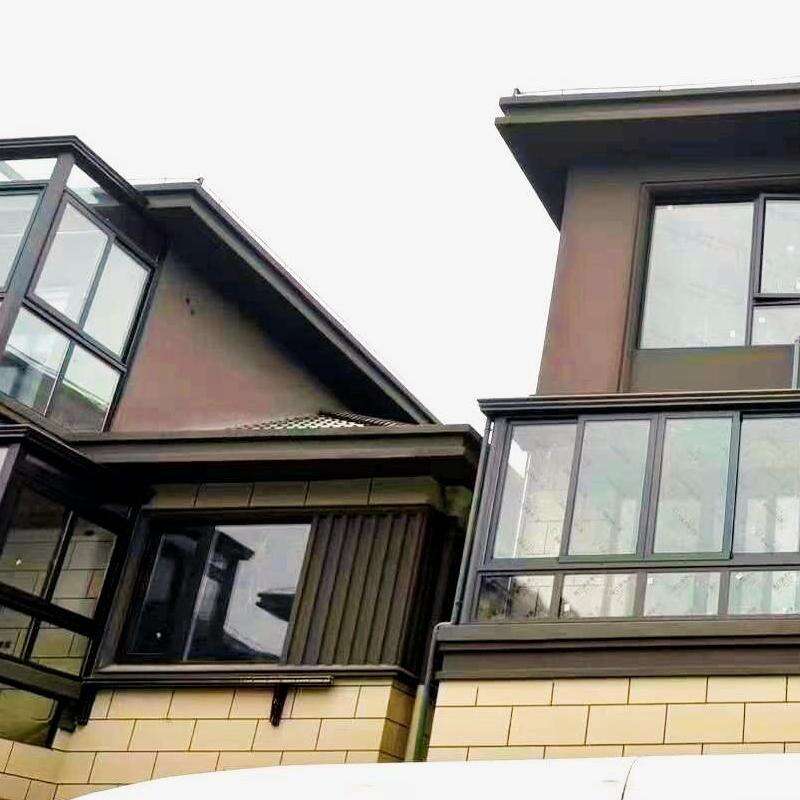

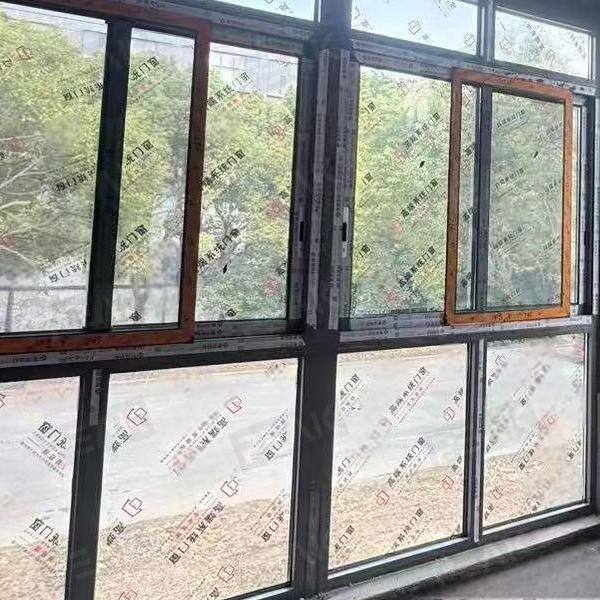

windproof & waterproof thermal break aluminum doors and windows supplier

A windproof & waterproof thermal break aluminum doors and windows supplier represents the pinnacle of modern architectural fenestration solutions, offering comprehensive manufacturing and distribution services for high-performance building envelope systems. These specialized suppliers focus on delivering advanced aluminum-framed door and window systems that incorporate cutting-edge thermal break technology, ensuring superior energy efficiency and weather resistance. The primary functions of a windproof & waterproof thermal break aluminum doors and windows supplier encompass design consultation, precision manufacturing, quality assurance, and comprehensive installation support. Their core technological features revolve around thermal break aluminum profiles that effectively interrupt heat transfer pathways, creating a barrier between interior and exterior aluminum components. This thermal separation is achieved through polyamide strips or thermal barriers that significantly reduce thermal conductivity while maintaining structural integrity. The waterproofing capabilities stem from advanced sealing systems, including EPDM gaskets, weatherstripping, and multi-chamber drainage designs that channel moisture away from critical areas. Wind resistance is accomplished through reinforced frame construction, multi-point locking mechanisms, and structural glazing techniques that distribute wind loads effectively across the entire system. Applications for these systems span residential developments, commercial buildings, institutional facilities, and industrial structures where energy efficiency and weather protection are paramount. The supplier typically serves architects, contractors, developers, and homeowners seeking premium fenestration solutions that meet stringent building codes and performance standards. Modern windproof & waterproof thermal break aluminum doors and windows supplier operations incorporate sophisticated manufacturing processes, including CNC machining, powder coating, and precision assembly techniques that ensure consistent quality and dimensional accuracy. Their expertise extends to customization capabilities, allowing for bespoke designs that accommodate unique architectural requirements while maintaining optimal performance characteristics.