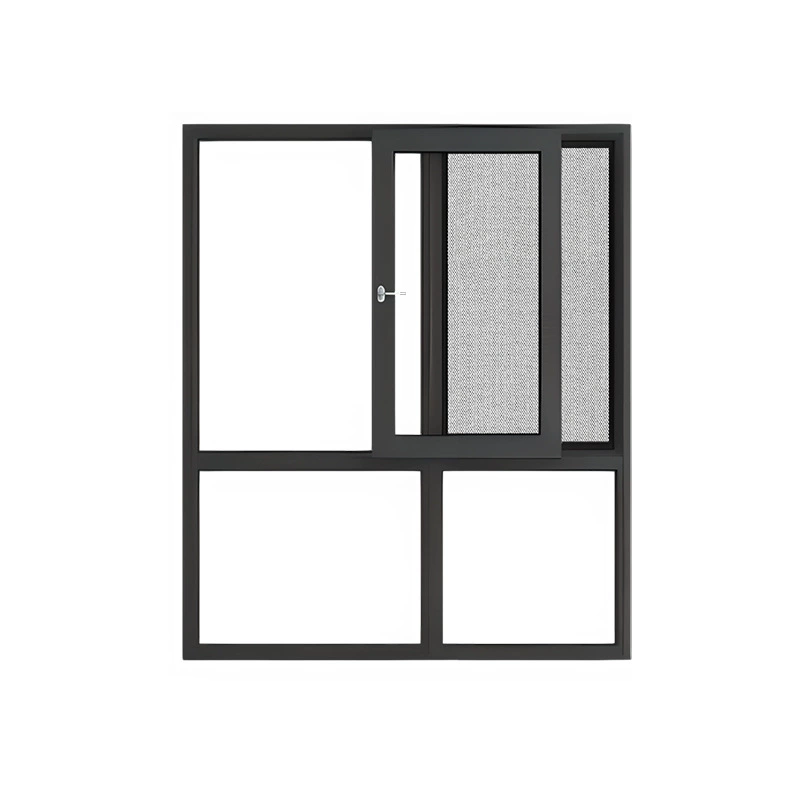

thermal break aluminum doors customization

Thermal break aluminum doors customization represents a revolutionary approach to modern architectural solutions, combining energy efficiency with personalized design elements. This advanced door system incorporates specialized thermal barrier technology that effectively separates the interior and exterior aluminum profiles, preventing heat transfer and maintaining optimal indoor temperatures. The customization aspect allows property owners to tailor these doors according to their specific requirements, including dimensions, finishes, hardware selections, and glazing options. The thermal break aluminum doors customization process utilizes high-performance polyamide strips strategically placed between aluminum sections, creating an insulating barrier that significantly reduces thermal conductivity. These doors feature multi-chambered aluminum profiles that enhance structural integrity while maximizing thermal performance. The technology incorporates precision engineering with advanced sealing systems, weather stripping, and compression gaskets that ensure airtight closure. Modern thermal break aluminum doors customization includes sophisticated locking mechanisms, adjustable hinges, and corrosion-resistant hardware components. The applications for these customized door systems span residential, commercial, and industrial sectors, making them suitable for luxury homes, office buildings, retail establishments, hotels, and manufacturing facilities. The customization process encompasses various design elements including color matching, surface treatments, decorative glass panels, and architectural detailing that complement existing building aesthetics. These doors excel in extreme weather conditions, providing reliable protection against wind, rain, snow, and temperature fluctuations. The thermal break aluminum doors customization technology supports sustainable building practices by reducing energy consumption, lowering carbon footprints, and contributing to green building certifications. Professional installation ensures optimal performance, while the customization options allow seamless integration with existing architectural elements and design themes.