Comprehensive Customization Flexibility

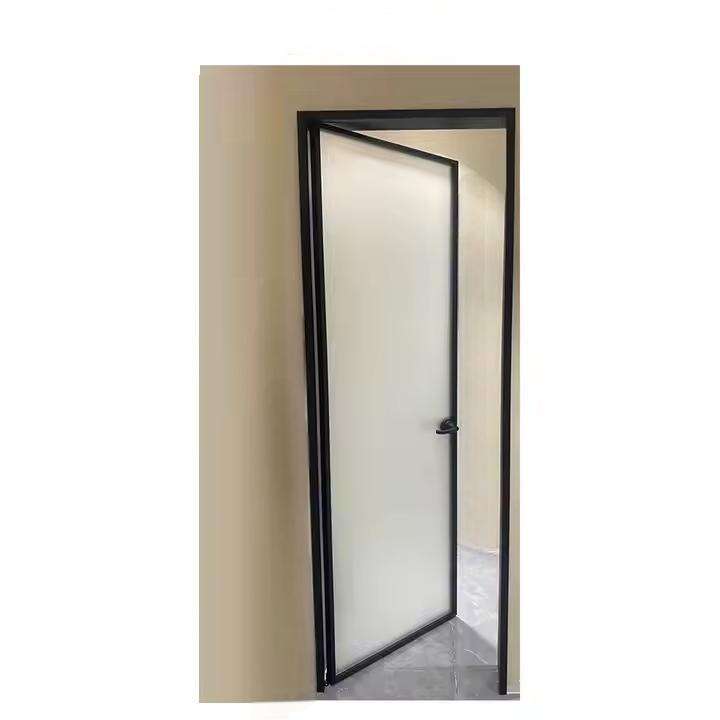

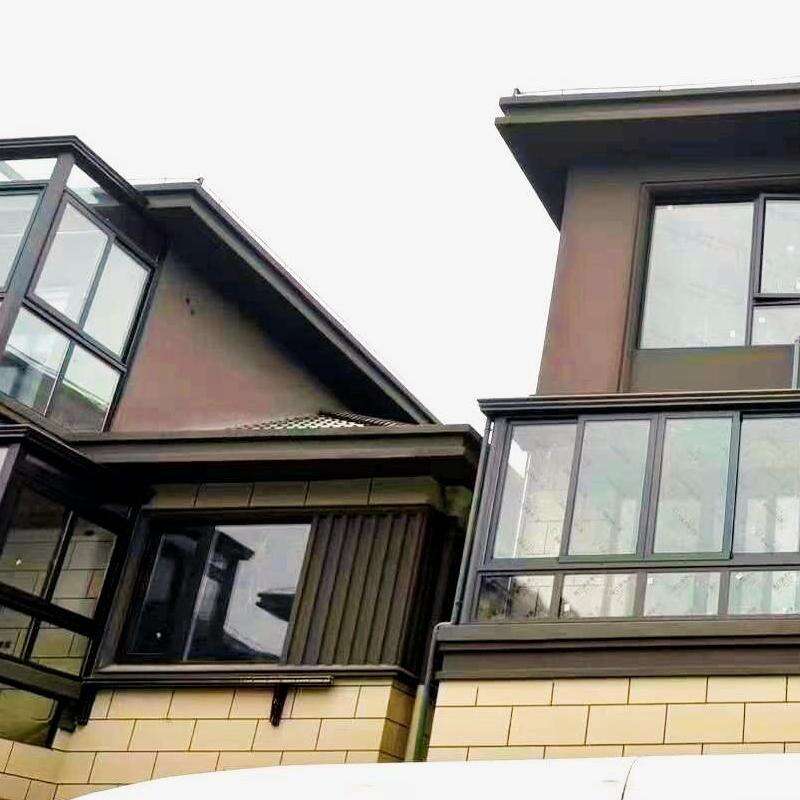

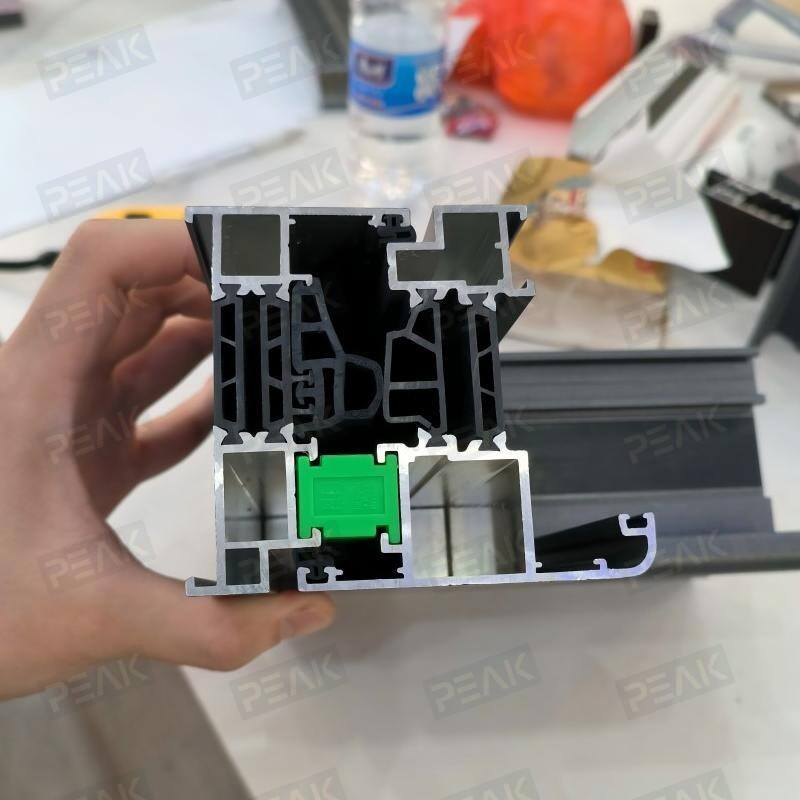

The comprehensive customization flexibility of durable thermal break aluminum doors and windows customization empowers architects, builders, and property owners to create bespoke solutions that perfectly align with specific design requirements and functional objectives. This extensive customization capability encompasses dimensional flexibility that accommodates non-standard openings, unique architectural features, and specialized installation requirements without compromising thermal performance or structural integrity. The design process begins with detailed consultations where technical specialists analyze architectural drawings, site conditions, and performance specifications to develop tailored solutions that optimize both aesthetic appeal and functional efficiency. Frame profiles are available in numerous configurations, including different depths, widths, and geometric shapes that complement various architectural styles from ultra-modern minimalism to classical traditional designs. Color customization options extend beyond standard powder coating selections to include custom color matching, wood grain finishes, and specialty textures that seamlessly integrate with existing building materials and design themes. Hardware selection encompasses multiple operating mechanisms including casement, awning, sliding, tilt-and-turn, and fixed configurations, with options for manual or motorized operation systems that enhance convenience and accessibility. Glazing customization allows specification of various glass types, thicknesses, and performance characteristics including impact resistance, sound dampening, privacy options, and specialized coatings for solar control or bird strike prevention. Security features can be integrated during the customization process, incorporating reinforced frames, laminated glazing, multi-point locking systems, and alarm integration capabilities that meet specific security requirements. The manufacturing flexibility extends to installation considerations, with custom mounting systems, weatherproofing solutions, and integration details that ensure proper performance in unique building envelope conditions. Project management services coordinate customization processes from initial design through final installation, ensuring that complex projects maintain schedule adherence and quality standards. Technical support continues beyond installation with maintenance protocols, replacement part availability, and performance monitoring services that protect the long-term investment value of customized systems.